Multi-Channel Flaw Detectors for Ultrasonic Testing Across Industries

The complexity of technological processes in metallurgy, mechanical engineering, and other industries requires the simultaneous monitoring of numerous product quality parameters from various measurement points, as well as a rapid response to any deviations. These challenges can be addressed using a multi-channel flaw detector, to which multiple ultrasonic probes can be connected, ensuring both flexibility and efficiency in the inspection system.

Each multi-channel flaw detector is a standalone electronic unit designed as a module with a configurable number of ultrasonic channels, ranging from one to eight depending on the model. Each module can connect to a PC via an Ethernet port. Furthermore, these flaw detectors can easily be combined to create larger automated or semi-automated quality inspection systems that can be scaled to meet specific production requirements.

Primary Industrial Uses of Multi-Channel Flaw Detectors

- Ultrasonic testing (UT) of rolled steel bars, axles, shafts, and pipes. Inspection systems equipped with multiple multi-channel flaw detectors can identify various types of internal defects in round rods of different diameters, including those that occur during the rolling process. These systems can also test the material for internal discontinuities and changes in ultrasonic signal attenuation.

- Non-destructive testing (NDT) of flat-rolled steel products. This includes sheets, plates, rolls, tapes, strips, stampings, and other similar products. These products can be up to 7.87 inches (200 millimeters) thick. The entire product, including the edges or areas to be welded, is scanned. Defects (internal discontinuities) in the metal are detected during scanning, and their parameters are measured. The acceptability of the product is then determined based on these measurements.

- Measuring the thickness of extremely thin tubes with walls as small as 0.008 in (0.2 mm). The multi-channel flaw detector can be integrated into the production process or used autonomously in a laboratory setting. It can evaluate the depth of cracks in tubes starting from 0.002 in (0.05 mm).

- Testing of welded joints. Testing of welds. Monitoring systems that include multi-channel flaw detectors provide ultrasonic testing of welded joints and heat-affected zones (HAZs) on pipes and pipe ends. These systems also measure pipe thickness.

Railway Applications of Multi-Channel Flaw Detectors

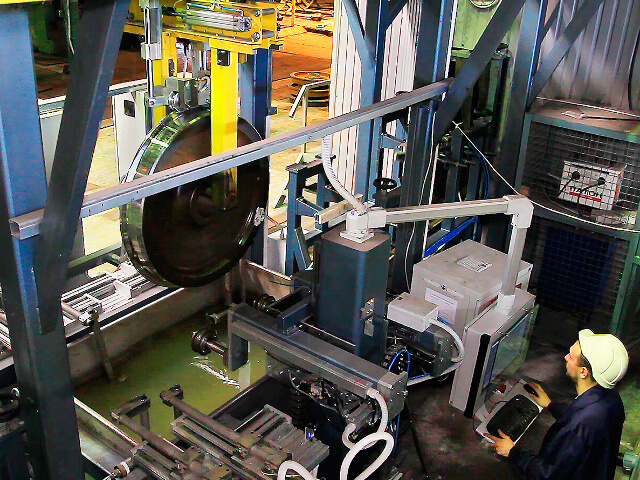

- Ultrasonic testing of railway wheel pairs. Multi-channel flaw detectors can be used at depots or directly on production sites. These devices allow for the detection of internal defects in rims, disks, and axles. They also detect hidden defects in wheel rims, including fatigue cracks in rim chamfer areas and flanges. Multi-channel flaw detectors assist in determining the depth and extent of these flaws. They support accurate service life prediction and the timely withdrawal of wheel pairs from operation

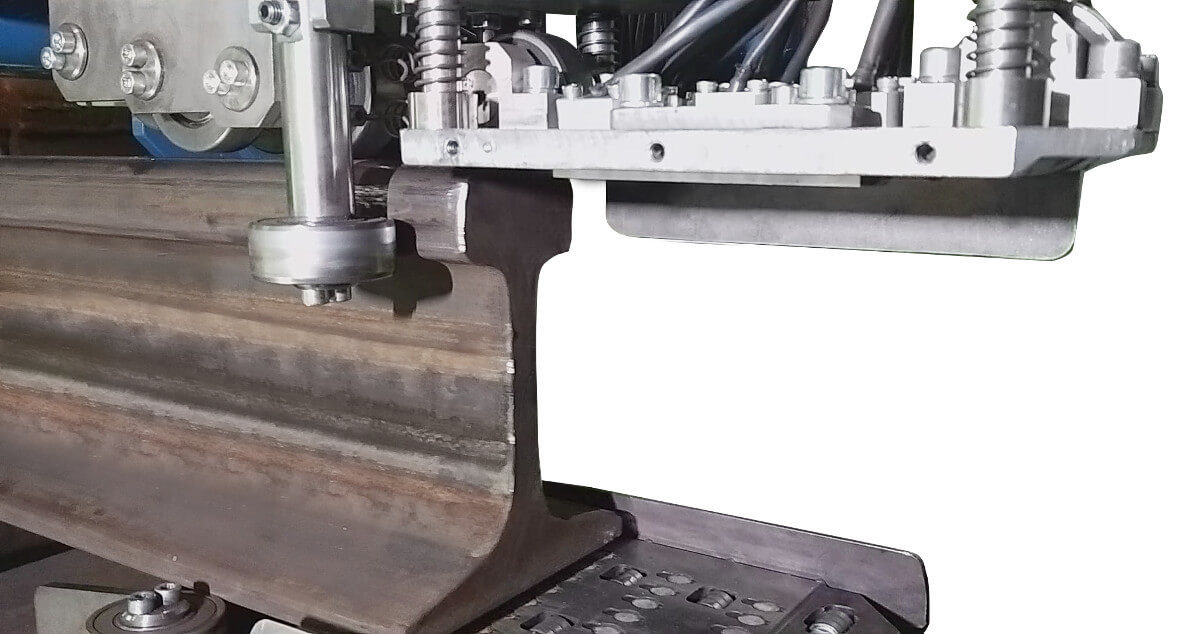

- Rail flaw detection. Multi-channel flaw detector modules are used in the design of rail flaw detectors and high-speed ultrasonic rail testing Systems that are installed on tracks. They are also used in the rail manufacturing process for the simultaneous non-destructive testing (NDT) of multiple rail zones. During this process, internal defects such as cracks, voids, and inclusions are identified and assessed after rolling, heat treatment, and forming. This enables defective areas to be removed promptly before further processing.

Sales & Development Proposals

OKOndt GROUP offers NDT specialists and companies a standard UT solution or the individual development of a flaw detection system with multi-channel flaw detectors. Our ultrasonic testing equipment provides scalable, high-performance continuous monitoring of multiple parameters, ensuring fast, reliable, and precise quality control across production lines.

Contact us for more information about tailored configurations, technical support, and how our ultrasonic NDT equipment can meet your industrial and inspection requirements.

Related products:

About OKOndt GROUP

OKOndt GROUP is a group of companies with more than 30 years of experience in researching, developing, and producing nondestructive testing (NDT) equipment for industrial customers worldwide. The production companies in the group are Ultracon-Service LLC and Promprylad LLC.

Need help?