Automated testing

OKOndt GROUP™ provides users with a large number of ultrasonic testing machines outfitted for the purposes of automated nondestructive testing.

Mechanized NDT systems are used for solving testing tasks in a variety of situations where the use of portable flaw detectors is either problematic or impossible, for example, the complex testing of railcar wheelsets. Nondestructive testing systems are usually based on three automated NDT methods: ultrasonic, magnetic, and eddy current.

Automatic ultrasonic testing is mainly used in large-scale inspection tasks, such as longitudinal pipes or railway axles. The conventional ultrasonic testing system developed by OKOndt GROUP™ is capable not only of testing, but also collecting and recording test data for post-processing.

Magnetic methods are either used independently or in combination with other nondestructive testing techniques to acquire valid information about the condition of the test object. Nondestructive testing based solely on the magnetic NDT method gives the users highly accurate information about the surface condition of the test object.

Eddy current systems are used for testing complex parts and/or critical structural elements, or as a supplementary tool for other methods. The eddy current technique is common in avionics, as well as in the inspection of rail wheels and longitudinal tubes.

To obtain comprehensive and accurate information about test objects, the methods described above can be combined in an integrated inspection system. For example, ultrasonic systems paired with magnetic subsystems are widely used for testing rail wheels. The combination of different nondestructive methods in a hybrid NDT system compensates for the shortcomings of individual techniques and ensures an accurate and complete assessment. Nondestructive testing solutions manufactured and configured by OKOndt GROUP™ are highly reliable and precise, capable of conducting comprehensive tests in various objects. Data recorded by ultrasonic, magnetic, or eddy-current nondestructive testing systems can also be used for post-processing, allowing users to further increase the test accuracy. Below, you can see some examples of our nondestructive testing systems intended for different purposes.

More... »

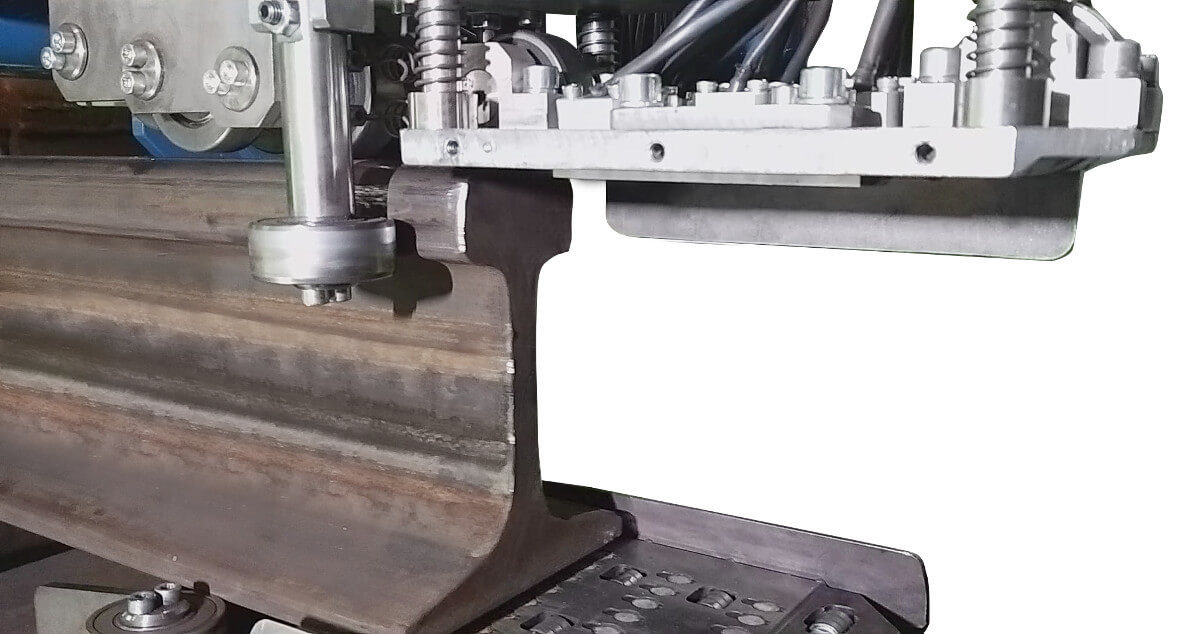

EDC RAIL 5065 Eddy-Current Testing Machine is designed for automated non-destructive testing of railway rails by eddy-current method in the course of their manufacturing. The presence of surface defects such as outer surface cracks of the rail heads, flutings and railway rails base of R50, R65, R65K, 60E1, UIC60 types is tested according to DIN EN 13674-1-2017.

Read more ...

The System is intended for work in assembly with the line of quality control of wheel and rim products.

Read more ...

AUTS Axle-4 OS-4 System is designed for automated ultrasonic inspection of railcar wheels axles during production and after repair.

Read more ...

The SNK B-35 (L) is designed to automatically detect inadmissible internal and external defects of the roll body (breaking of the continuity of the metal such as: reed mark, slag inclusion, crack, fold, cleavage, etc.) with the issuance of protocols on the usability.

Read more ...

SMARTSCAN Aircraft Wheel Inspection System is intended for testing of main and nose wheels of aircrafts of various world manufacturers such as Messier - Bugatti, Goodrich, Honeywell, Maggitt and others.

Read more ...

The automated line for magnetic particle and ultrasonic testing of railway wheel rim, hub, web and flange to be integrated into the wheel inspection station.

Read more ...