OKOndt GROUP Manufactures Ultrasonic and Eddy Current Testing Equipment

At OKOndt GROUP, we design and manufacture advanced nondestructive testing (NDT) equipment, including ultrasonic and eddy current flaw detectors, and systems that help industries ensure the safety, reliability, and integrity of their materials and structures.

OKOndt GROUP's NDT solutions are trusted in over 70 countries and are used for rail, weld, and aircraft wheel inspection, as well as many other critical industrial applications worldwide. Our instruments enable real-time NDT inspections of test objects without damaging the material and effectively detect critical defects in materials, structures, and components at any stage of production or operation. They ensure effective quality control and minimize industrial downtime.

Explore the Full Range of Our NDT Products

The diversity of NDT methods and techniques has led to a wide range of flaw detectors, including ultrasonic (UT), eddy current (ET), and electromagnetic acoustic (EMA) testing systems. Each instrument is designed for use with one or more of these methods, ensuring reliable detection in specific applications. Beyond flaw detection, many instruments provide additional capabilities; for example, portable UT detectors also support thickness gauging.

Specialized NDT Devices, Systems, and Accessories for Diverse Applications

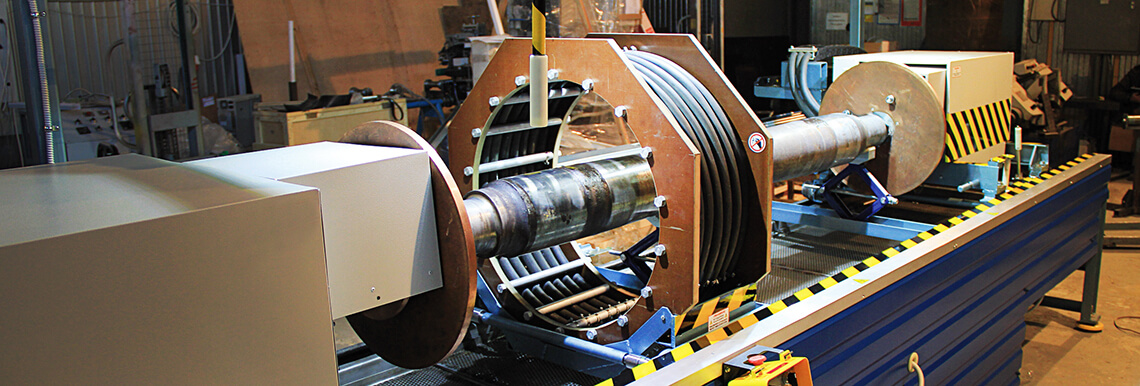

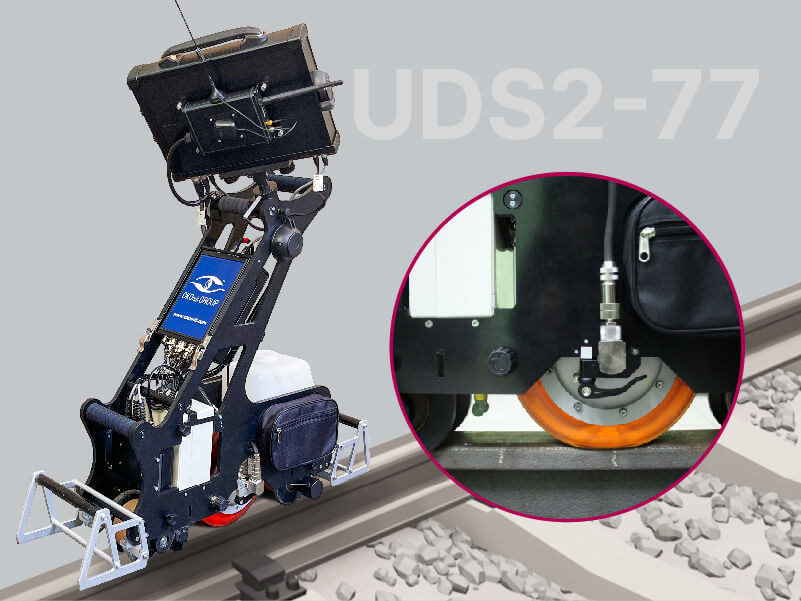

- Ultrasonic Devices and Automated Systems – provide precise flaw detection for rails and welded rail joints, thickness measurement of components, and a wide range of other industrial applications. Advanced TOFD instruments are also available.

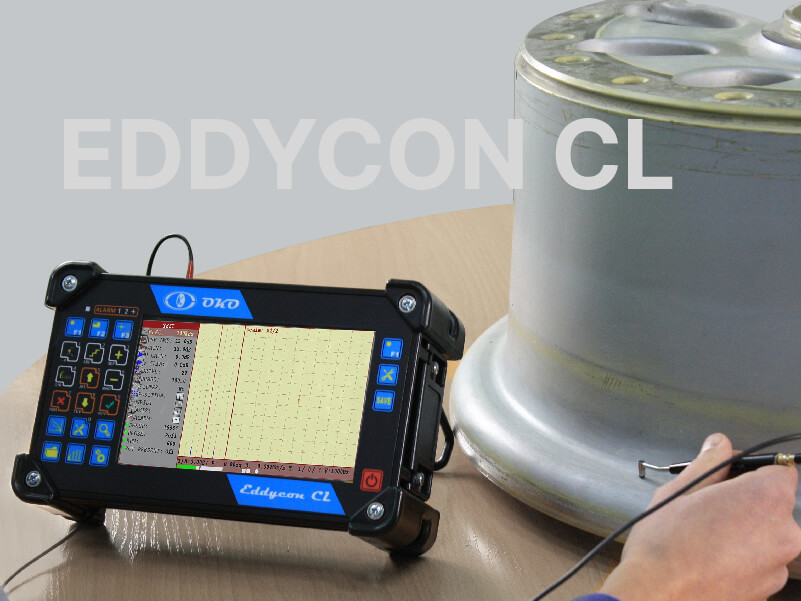

- Eddy Current Instruments and Automated Systems – ensure fast and reliable inspection of aircraft components, including wheels and assemblies, as well as applications across other industrial sectors.

- Electromagnetic Acoustic (EMA) Instruments – support metallurgy and engineering applications such as testing steel rods, slabs, welded pipe joints, and pipe bodies, with additional capabilities for thickness gauging.

- Software, Sensors, and Accessories – from OKOndt GROUP, designed to expand system functionality and make inspection more efficient.

Key Factors for Choosing Ultrasonic and Eddy Current Flaw Detectors

It is important to consider the specific NDT tasks and conditions under which testing will be performed when choosing a flaw detector.

- Test object. The NDT equipment must be adapted to the specific material and geometry of the product under test. Hand-pushed trolleys and automated high-speed Systems with integrated ultrasonic and eddy current flaw detectors are used to inspect rails in track and welded joints. Portable hand-held flaw detectors are applied for spot testing of metal products, including pipes and rolled stock. Complex nondestructive testing Systems that combine multi-channel ultrasonic and eddy current flaw detectors are used in industrial production. These Systems can incorporate from a few to several hundred flaw detectors for testing different objects.

- Type of defects. Industry NDT standards must be considered because they define the types, dimensions, and permissible locations of critical defects within the material. Eddy current instruments are used to detect surface and near-surface defects, such as shallow cracks in aircraft wheels or headchecks on rails. Ultrasonic flaw detectors reveal internal defects, including deep cracks and material delamination. These inspection tools are widely used in rail and weld testing, as well as in production line quality control across many industries.

- Operating conditions. In industrial environments, reliability is essential. The portable flaw detector should be comfortable to hold, capable of clipping to clothing or a belt, and mountable on a work surface. For railroad NDT inspections, reliable operation in both freezing and high-heat conditions is critical. For harsh environments, the NDT instrument and Multi-Channel Systems should feature a rugged, shock-resistant, moisture- and dust-resistant enclosure (e.g., IP-rated). Its probes can be configured for high-temperature inspections; for example, EMAT transducers (EMA method) used in metallurgy are available in high-temperature versions for hot-surface testing, where the test object may reach up to 1202 °F (650 °C).

Why Choose NDT Equipment from OKOndt GROUP

With over 30 years of expertise in nondestructive testing, OKOndt GROUP unites in-house development and manufacturing with rigorous quality control at every stage. We provide comprehensive customer support and training, while our advanced technologies comply with international standards to ensure reliable performance across industries worldwide.

All OKOndt GROUP equipment features an operator-friendly interface and built-in software with automatic signal interpretation. It’s backed by a manufacturer’s warranty, calibration and metrology support, and regional service. Our instruments meet industry standards and the certifications commonly required in aerospace, rail, power generation, and oil & gas. With secure data storage and audit-ready reporting, your team can document results clearly for NDT-inspectors and customers alike.

Get Your NDT Equipment

OKOndt GROUP catalog includes ultrasonic and eddy current rail flaw detectors, aircraft wheel crack inspection Systems, metal NDT equipment, and a full range of stationary machines and automated testing Systems for cross-industry NDT applications. All products are available for order.

Please use the contact form on our website to request a quote or check pricing before buying. Our specialists will help you select the configuration of your nondestructive testing equipment that best fits your NDT needs.

Meet us at world famous Annual Conferences and Exhibitions

Railway Interchange 2025

Indianapolis, Indiana, USA

Saudi Rail 2024

Riyadh, Saudi Arabia

Airlines for America (A4A 2024)

Nashville, Tennessee, USA

Innotrans 2024

Berlin, Germany

20th WCNDT (2024)

Incheon, South Korea

UPCOMING EVENTS

ECNDT 2026

June 15-19, 2026

Verona, Italy

Visit OKOndt GROUP at ECNDT 2026, the European Conference on Non-Destructive Testing – the premier international event of EFNDT. Discover our latest ultrasonic and eddy current NDT solutions.

Saudi Rail

October 19-20

Riyadh, Saudi Arabia

Meet OKOndt GROUP at Saudi International Rail 2025, the region’s key rail industry exhibition, where we will showcase advanced NDT solutions for rails, welds, and structural components of rolling stock.