The OKOSCAN UT 73HS PICKUP is a high-speed ultrasonic testing System that can continuously inspect rail tracks at speeds of up to 40 km/h (24.85 mph). It is installed on a hi-rail vehicle: a Ford F350 XL Super Duty.

The System consists of:

- A Ford F350 XL Super Duty with an installed Hi-Rail Kit

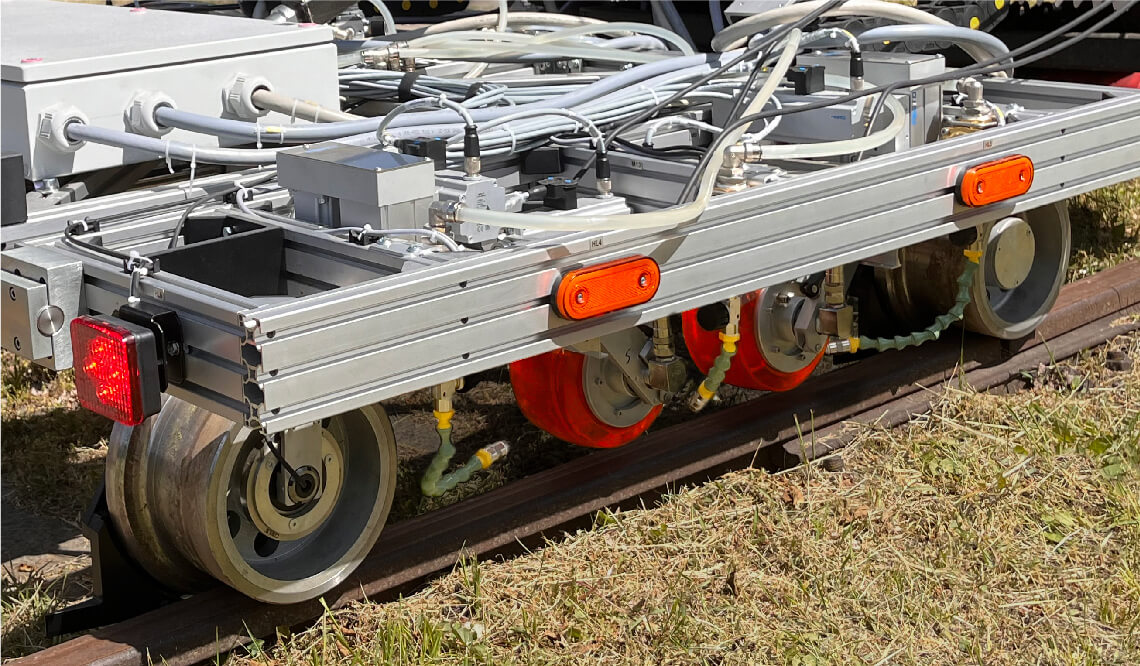

- An ultrasonic trolley follows the Ford F350 during rail testing. A built-in pneumatic system on the trolley adjusts the guide wheels to monitor the track gauge and keep the roller immersion search unit (SWP) aligned with the rail axis for accurate inspection.

- The equipment in the Ford F350 body includes UT channels and an automation and control box. It also features a hydraulic station, an air compressor, a liquid coupling container, a water supply system, and a hydraulic system for lifting and lowering the trolley. The operator's workspace with monitors is located on the rear seat in the cabin.

-

Vehicle:

- Ford F350 XL Super Duty.

- The Hi-Rail Kit combined running system. This system allows a Ford F350 XL, which is equipped with an ultrasonic rail testing system, to ride on both roads and railway tracks with a 56.5 in (1435 mm) track gauge. The rail system can be raised and lowered using an independent control panel inside the vehicle cabin or next to the rail unit.

Note: At the customer's request, a vehicle of a different brand with similar technical characteristics can be used. This will be discussed when ordering.

-

The trolley equipment:

- Four search wheels with immersion ultrasonic probes (SWP), two on each side of the trolley.

Each search wheel includes:

- 0° probe, 4 MHz – 1 pc

- 70° probe, 2 MHz – 3 pcs

- 50° probe (side looking), 2 MHz – 1 pc

- 37° probe, 2 MHz – 1 pc

- An SWP positioning system using stepper electric drives that are operator-guided (lifting/lowering, transverse displacement, and tilt).

- A pneumatic system that extends and retracts the trolley, which allows the operator to monitor the track gauge and thereby position the SWP along the rail axis.

- Encoder for tracking the path coordinates.

- A video surveillance system for the search wheels.

- A water supply system for the SWP with manual adjustment valves, tubes, and nozzles.

-

The vehicle body includes:

- Ultrasonic modules OKO-24 (at least 24 pcs) with frequency range from 1 to 7 MHz and pulsory repetition frequency (PRF) of up to 4 kHz.

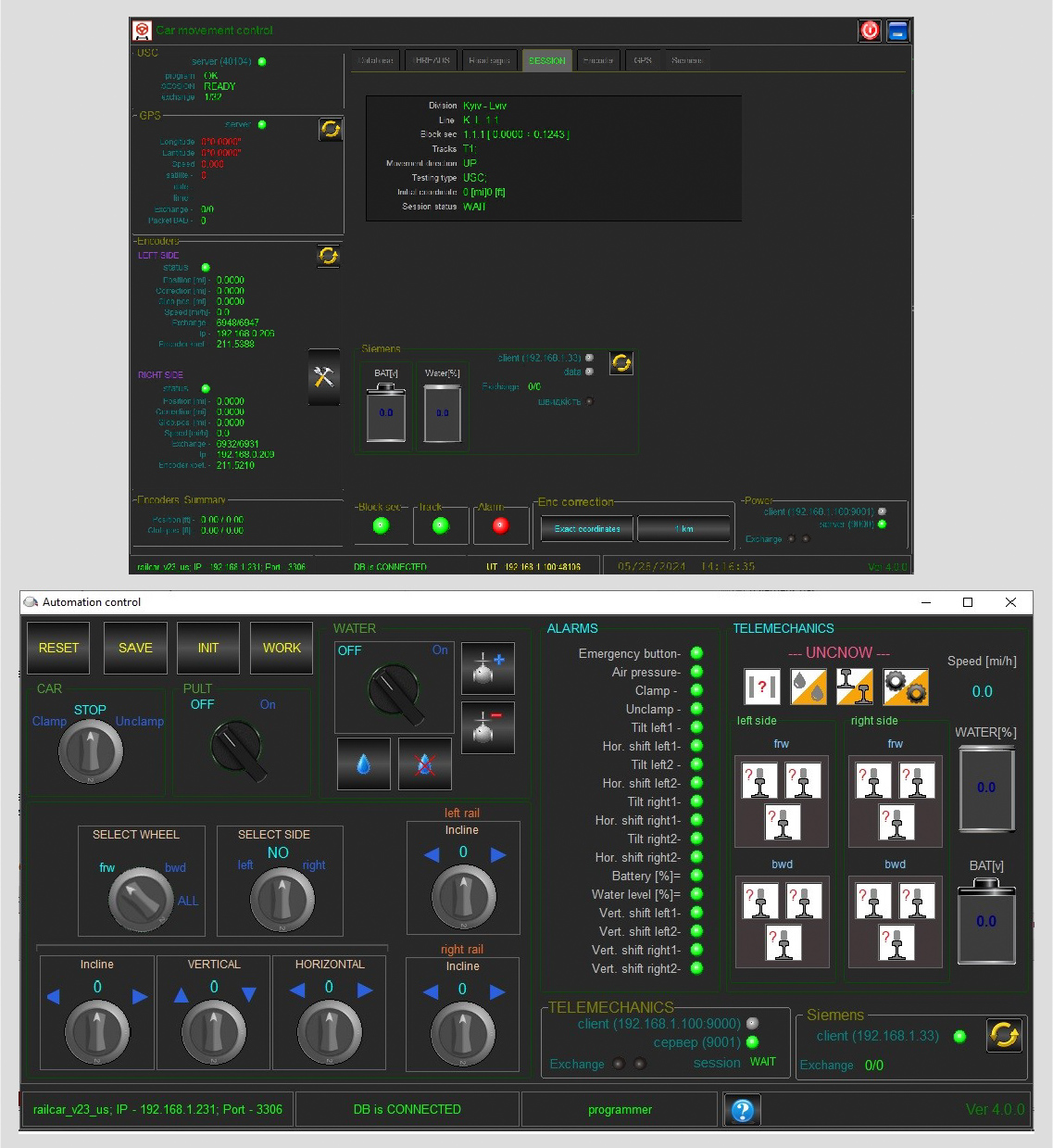

- Automation and control boxes

- Trolley lifting and lowering system with hydraulic station

- Air compressor for extending/retracting pneumatic system of trolley

- The vehicle body includes a water supply system under the SWP.

-

OKOSCAN UT 73 HS features:

- The trolley performs continuous ultrasonic testing (UT) of double-rail track along its entire length and cross-section, except for the rail foot flanges, at speeds of up to 24.85 mph (40 km/h).

- The track gauge under inspection ranges from 56.5 to 66 in. (1435 to 1676 mm) and can be modified upon the buyer’s request.

- The system allows detecting all types of defects: transverse and longitudinal horizontal cracks, cracks from bolt holes, etc. according to AREMA listing.

- The system measures defect parameters and saves inspection results to the database with the possibility of subsequent viewing and analysis.

- The System implements the following ultrasonic testing methods: pulse-echo and echo-shadow techniques.

-

OKOSCAN UT 73 HS’s hardware and computing system:

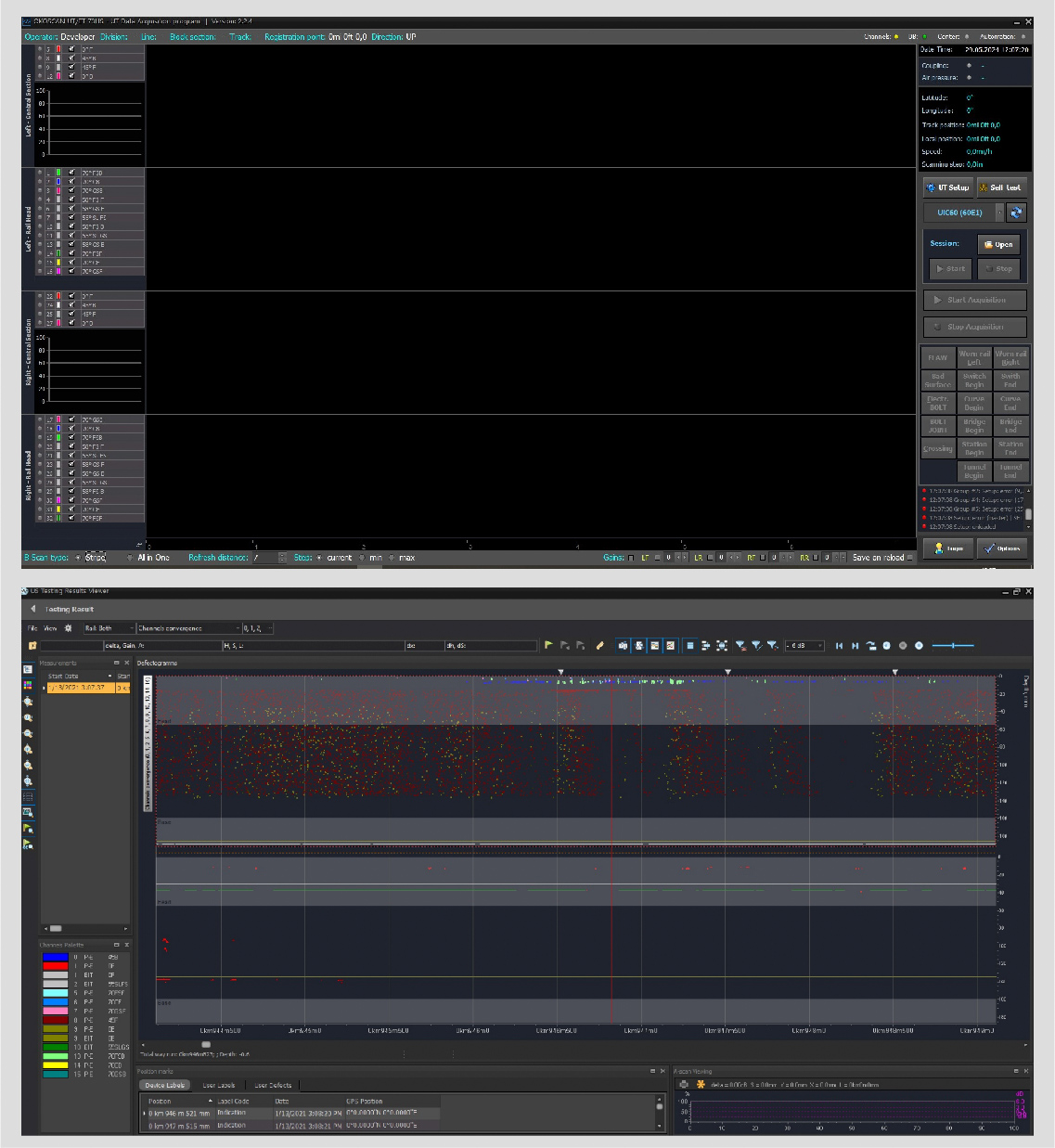

Equipment for processing and inspection results visualization is located at the operator’s workplace in the vehicle cabin.

The equipment provides for collection of inspection results data, visualization in various modes (A-scan, B-scan), generation of inspection reports, and the possibility of inspection results transmition through mobile operators via the 3G/4G protocol.

-

Pre-installed Software ensures the following functions:

- Automatic defect identification and their classification.

- UT control channels settings (gain, sweep parameters, RFC, probe parameters, gates parameters) and saving settings in storage.

- Inspection results visualization simultaneously in B-scan and A-scan modes for all channels in real time.

- Starting coordinate registration, inspection area data registration, track data registration.

- Viewing inspection results data with the possibility to implement all standard database management system functions (sorting and sampling according to agreed parameters).

- Formation of inspection protocols (also in Excel format).

- Memory capacity (HDD) allows you to save inspection results of at least 10,000 km of testing

- Automatic linking of the detected defect to path and GPS coordinates.