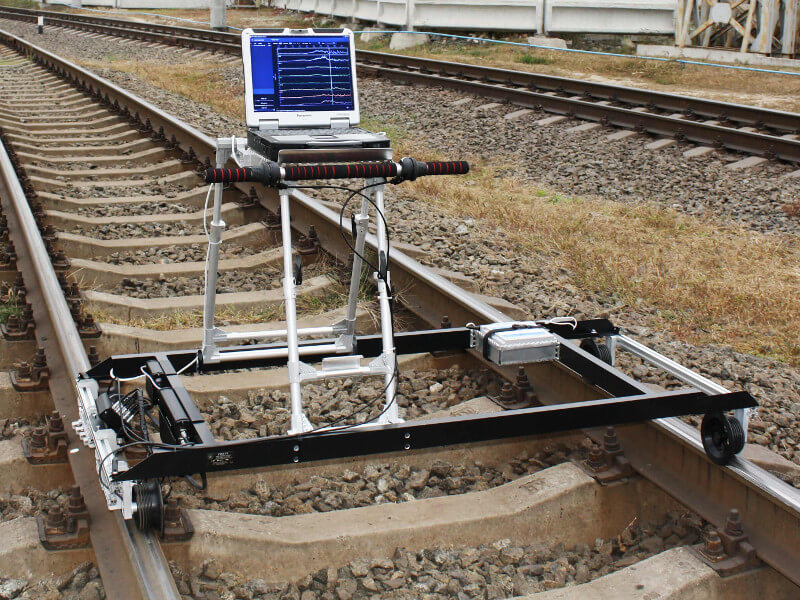

The ETS2-77 is intended for the mechanized inspection of rails and switches as well as confirmation of the results of a grinding application. The device is capable of testing a wide range of rail profiles.

Application

- possibility to control the rail track and the track switch;

- selective control of the separate rail track areas;

- post grinding machines control;

- all main rail profiles control Р50, Р60, 49E1, UIC 60 and others.

-

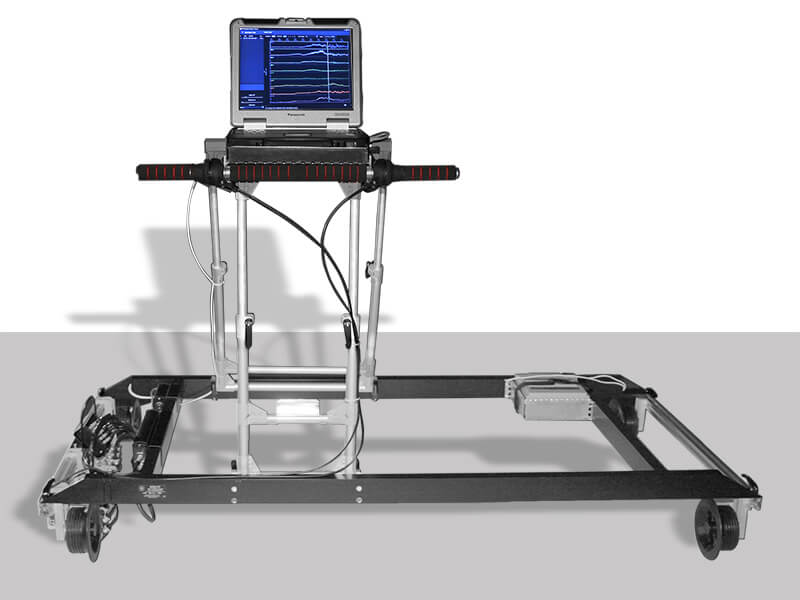

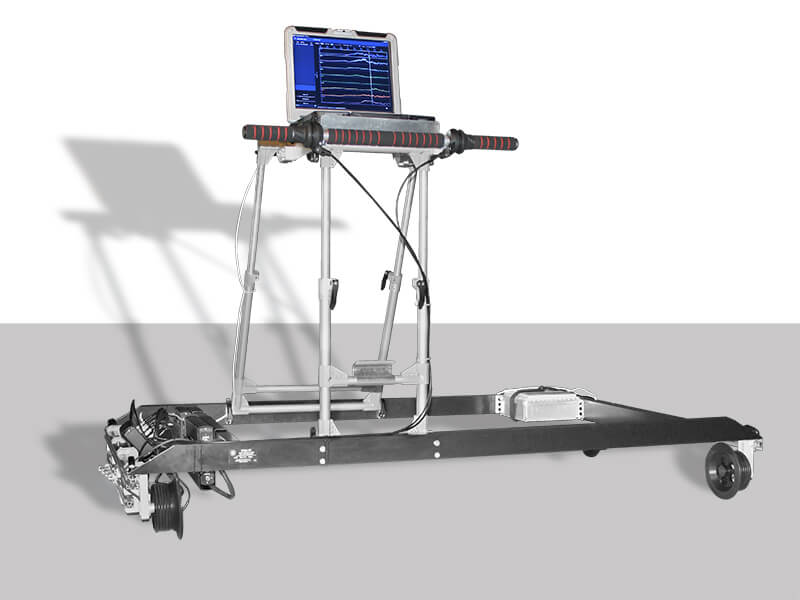

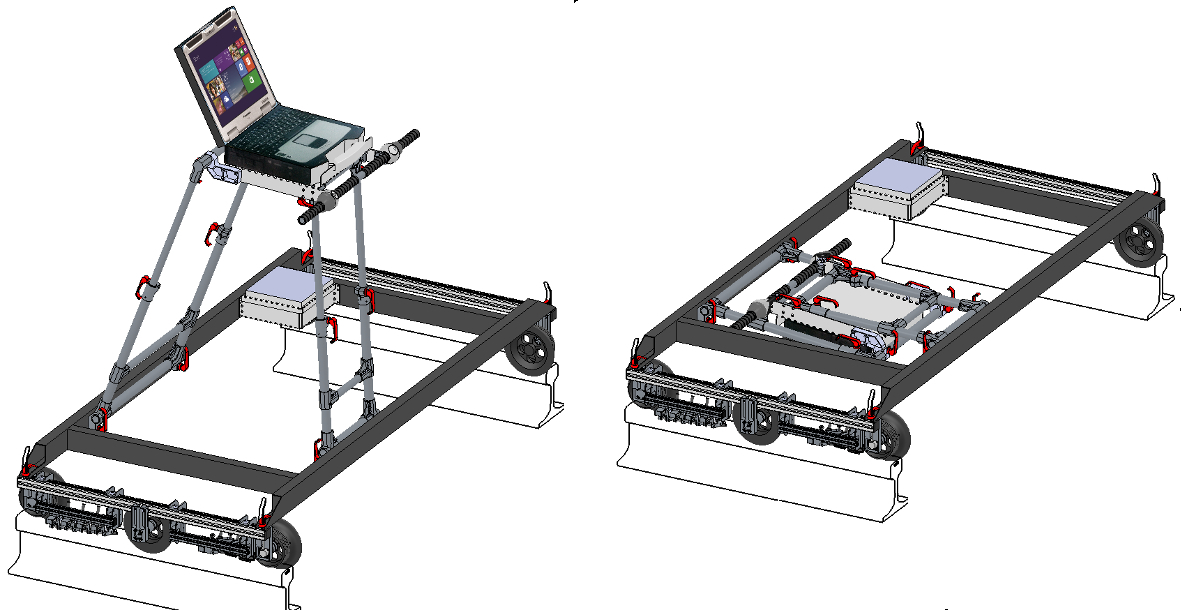

Lightweight and compact

Weight of the assembled flaw detector does not exceed 23 kg (50 lbs).

Overall dimensions of the assembled flaw detector are not more than:

- width - 900 mm

- length - 1730 mm

- height - 350 mm

The ETS2-77 flaw detector is a folding structure, which can be transported as it is a assembled in stowed position.

-

Main Components

- Aluminium base frame

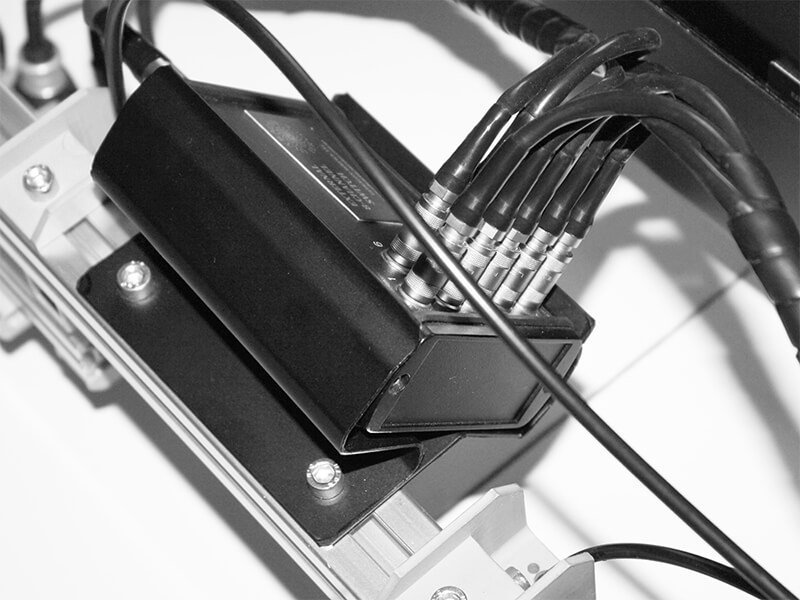

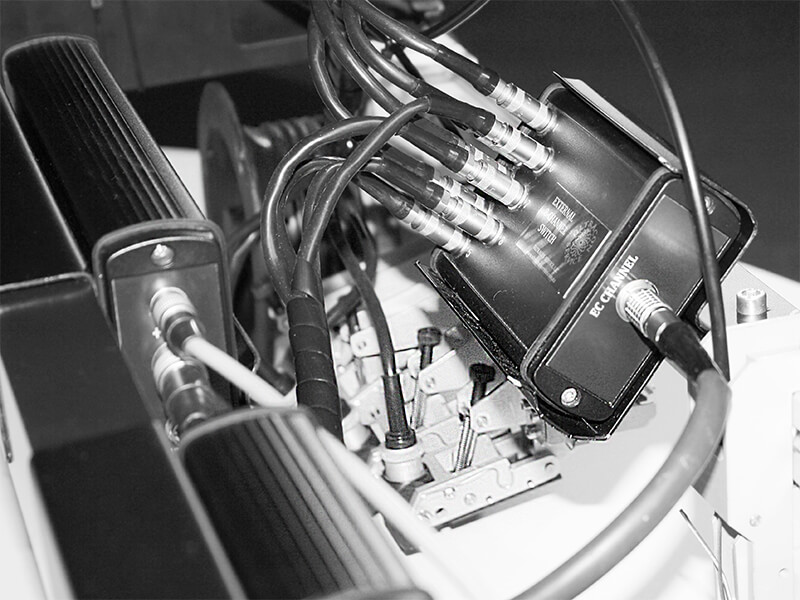

- Eddycon D - multichannel eddy current flaw detector

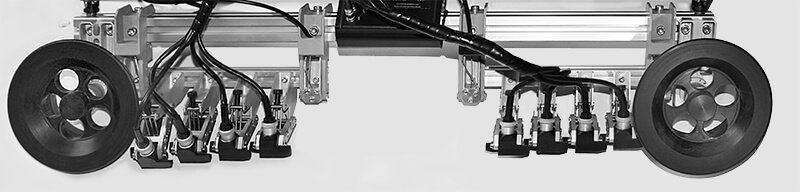

- Scanning modules with eddy current probes (ECP)

- Laptop

- Software for test data input, storage and processing

- Reference block

-

ETS2-77 intended use

The ETS2-77 is intended for the mechanized inspection of rails and switches as well as confirmation of the results of a grinding application. The device is capable of testing a wide range of rail profiles.

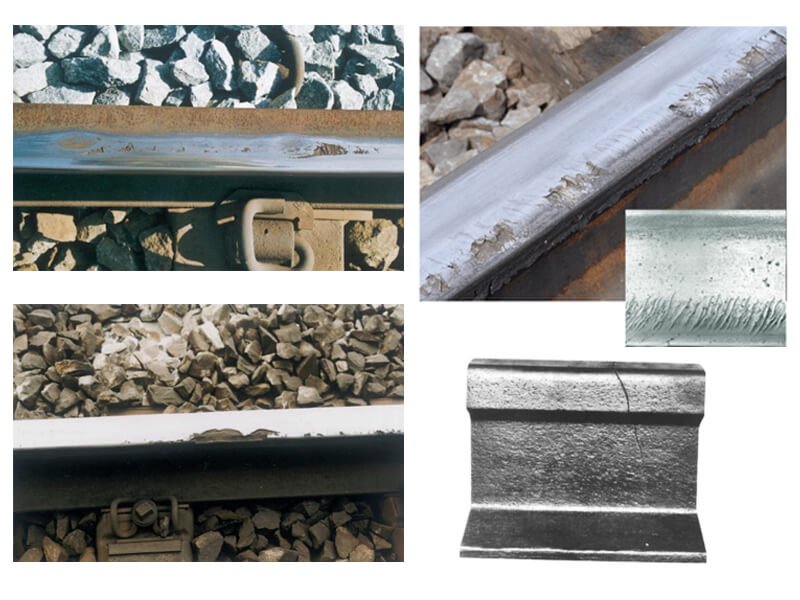

The eddy current technology enables localizing the following surface defects:

- progressive transverse cracking (International Defect Code (UIC) 211);

- fissuring /scaling at the gauge corner (International Defect Code (UIC) 2223);

- shelling of the gauge corner (International Defect Code (UIC) 2222);

- wheel burn (International Defect Code (UIC) 225).

The eddy current rail inspection equipment ETS2-77 is capable of evaluating the vertical depth of the defect, thus allowing a more efficient management of rail defects. The inspector can easily decide on the defect removal method: grinding, milling or re-railing, which saves time and money.

-

ETS2-77 flaw detector advantages

- light aluminum frame;

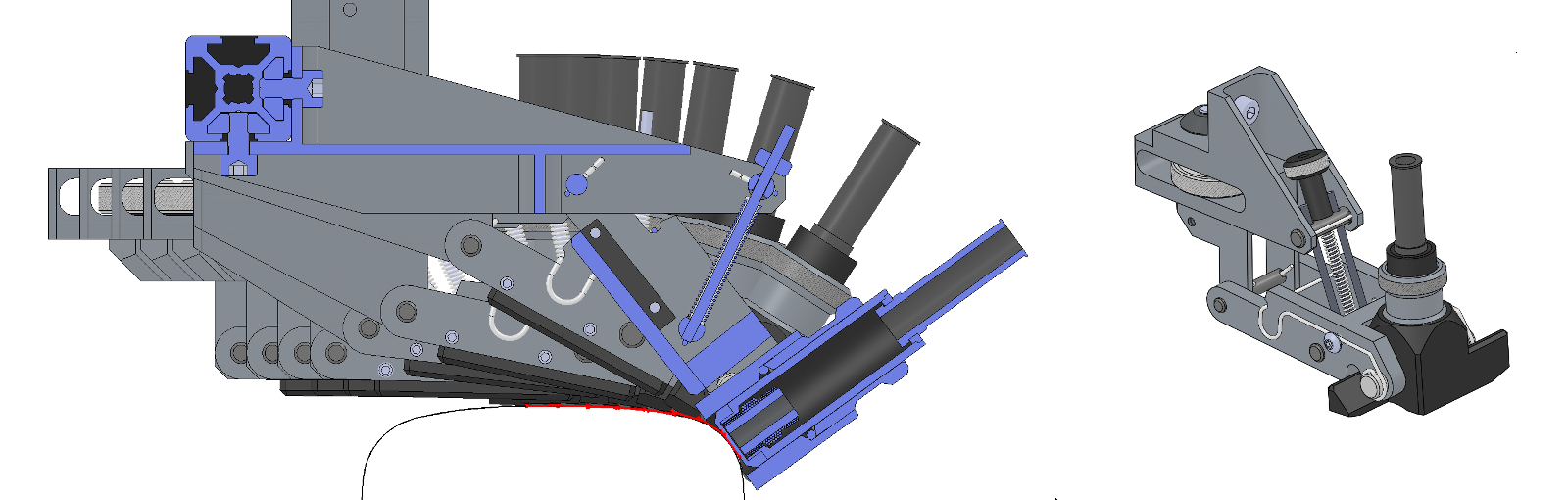

- specialized abrasion-resistant ECPs allow to evaluate the oblique cracks with up to 3 mm vertical damage depth;

- 8 ECPs application allows to perform the control of the whole head rail surface in one run;

- individual spring-mounted fitting of each ECP;

- fast removal of the scanner during the transfer from one area to another;

- individual adjustment of ECP position;

- operating time – not less than 8 hours;

- specialized SW for setting up, testing and inspection results review

-

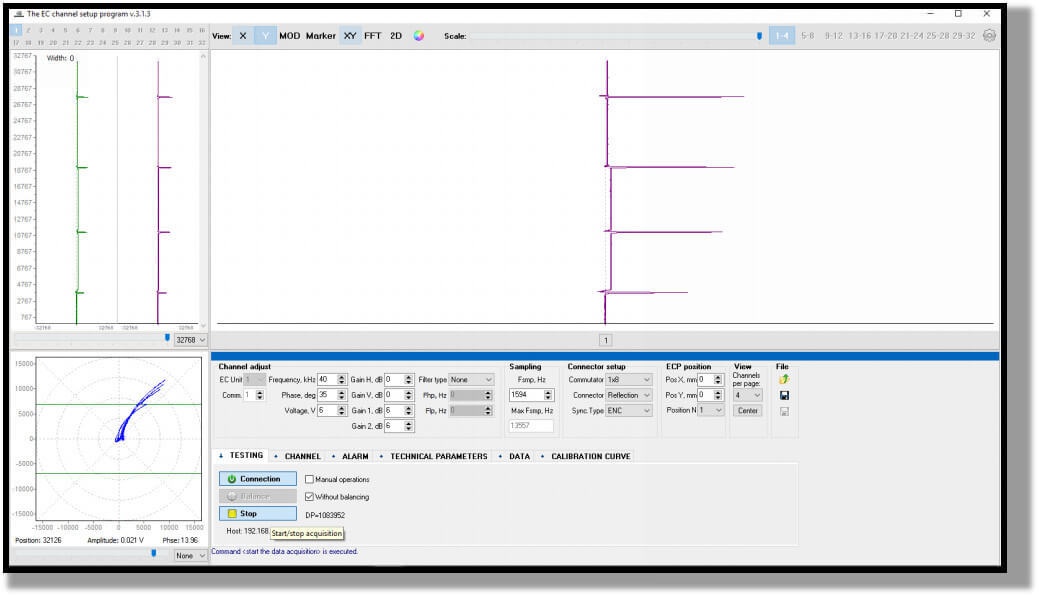

Program for setting up the EC channel

- Quick set up of all EC channel parameters – EC probe frequency, drive voltage, gain, filters, threshold level, sync type, etc

- Four independent threshold levels for automated defect triggering (ALARM) for each displayed area

- Saving the testing setups into the PC or tablet’s memory

-

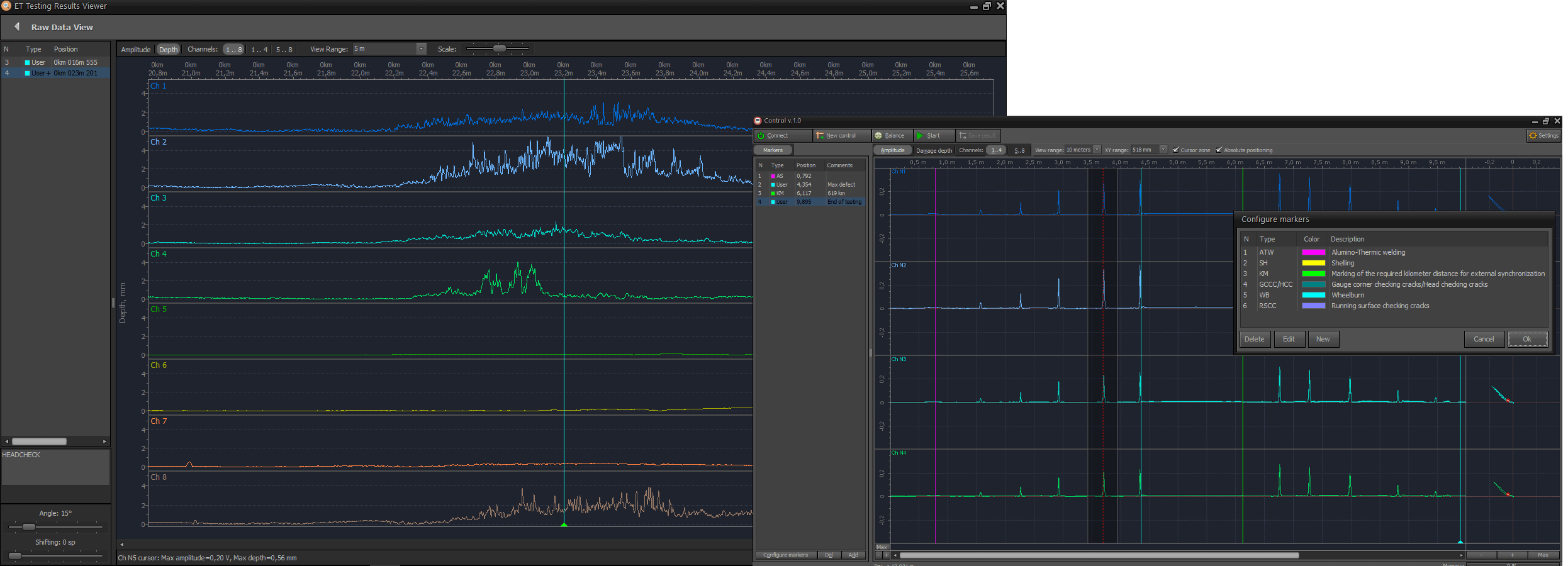

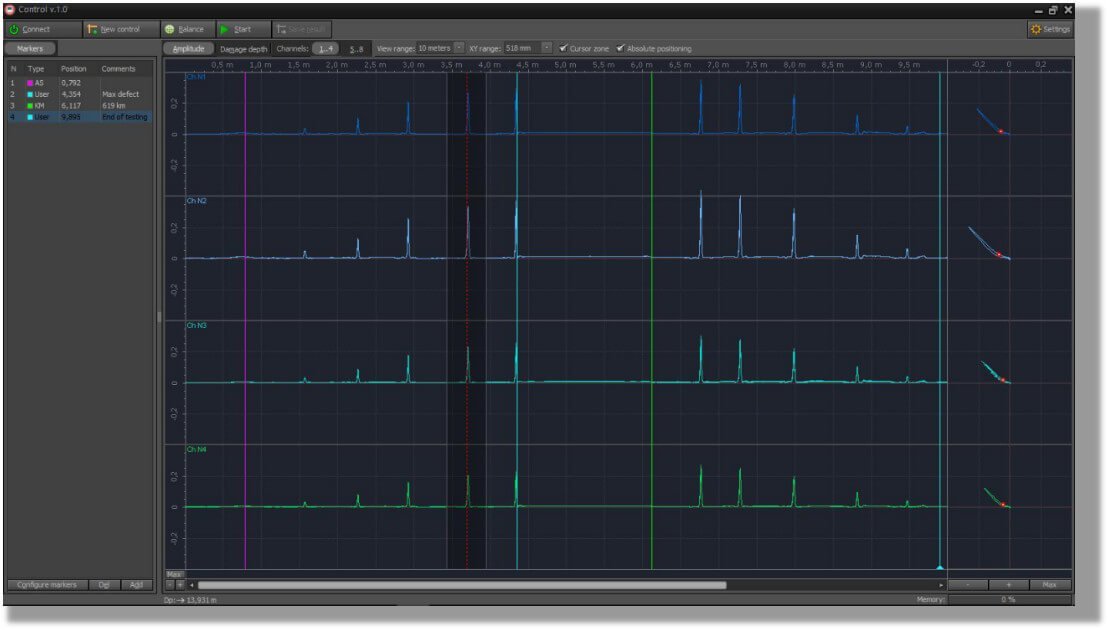

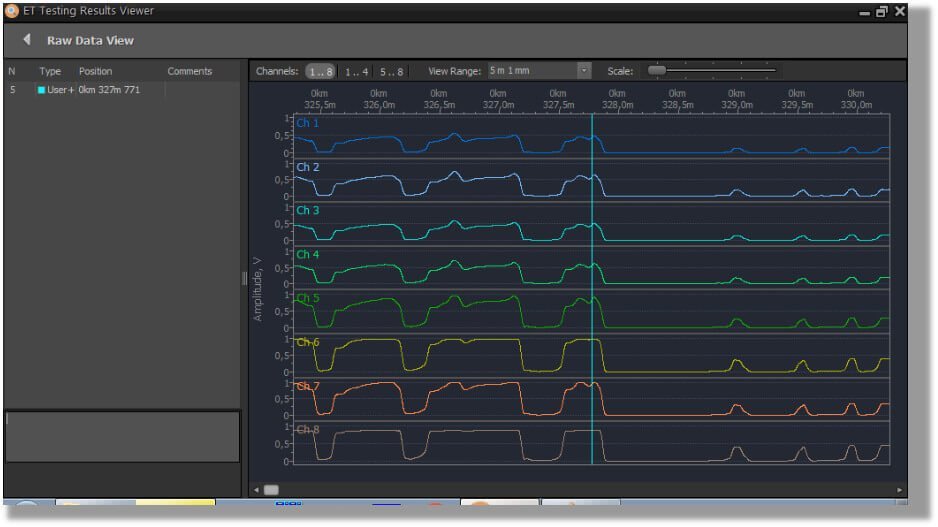

Program for the testing

- Real-time display of 8 EC probes information

- Recording the testing results into the PC or tablet memory

- Display of different types of information in the signal visualization area

- Re-calculation of the obtained defectograms

-

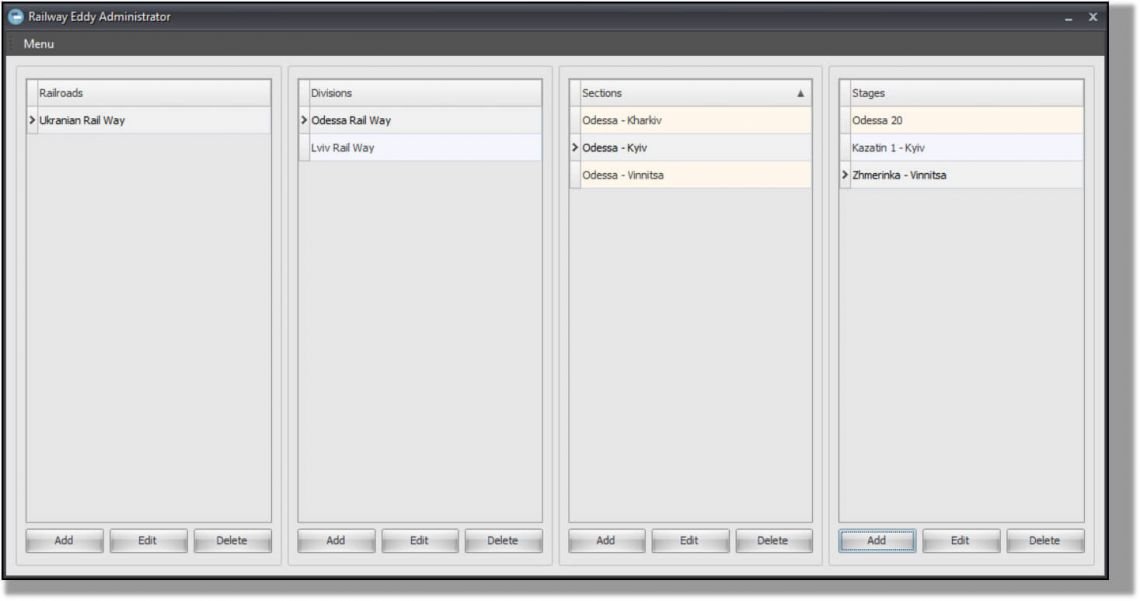

Program for generating the names of railroads

Consists of the following components:

Railroads – Divisions – Sectors – Stages

-

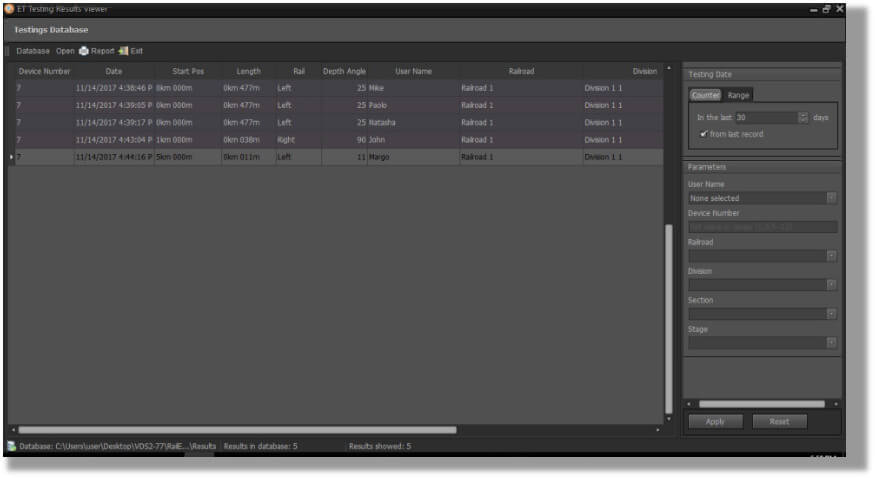

Program for reviewing the testing results

- Reading the test results from the database

- Printing out the test reports

- Archiving the test results

- Reviewing the test results from the remote PC , etc

SPECIFICATION

| Model | ETS2-77 |

| Flaw detector type | mechanized |

| Overall dimensions in the stowed position | 1730 mm × 900 mm × 350 mm |

| Eddy current channel | Eddycon D |

| Scanning device |

|

| ECP quantity | 8 |

| Tested area by one ECP | 6 mm |

| ECP protection from the abrasion and damage | Ceramic protective cover |

| Test velocity | Up to 2 m/s |

| Alarm | Visual |

| Specialized software |

|

| Operating time | 8 hours |

| Record and data storage | + PC hard disk |

| Working PC | Industrial one, IP rating 65 |

Should you have any questions, feel free to contact us