Straight Shaft Probe for sub-surface flaws detection in the second layer, through the first layer with up to 1.5 mm thickness (e.g., testing of load-bearing elements under aircraft skin) (Reflection type)

Straight Shaft Probe for sub-surface flaws detection in the second layer, through the first layer with up to 1.5 mm thickness (e.g., testing of load-bearing elements under aircraft skin) (Reflection type)

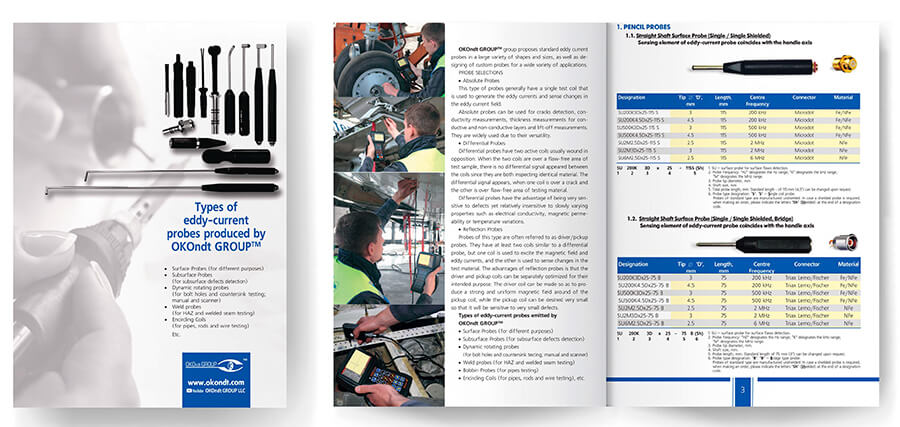

Straight ECP for Subsurface Flaws Detection in the Second Layer through the First Layer with Up To 1.5 mm Thickness:

- is an absolute probe built according to the “Reflection” scheme

- designed for testing of load-bearing elements under an aircraft skin

- applied together with the eddy current flaw detectors Eddycon C, Eddycon CL and flaw detectors from other producers.

|

Designation |

Outer diameter, mm/inch |

Length, mm/inch |

Frequency |

Connector |

Material |

Detected flaws |

|

SSP3K11DASh |

11/.43 |

39/1.5 |

1-25 kHz |

Lemo 04 |

NFe |

in aluminum through skin with up to 1.5 mm thickness |

|

in titanium at 5 mm depth |

||||||

|

SSP25K7DA |

7/.28 |

50/2 |

12-40 kHz |

Lemo 04 |

NFe |

in aluminum through skin with up to 1.5 mm thickness |

|

SSP25K10DA1 |

10/.39 |

50/2 |

12-40 kHz |

Lemo 04 |

NFe |

in aluminum through skin with up to 1.5 mm thickness |

|

SSP25K10DA0 |

10/.39 |

50/2 |

12-40 kHz |

Triax Lemo / Fischer |

NFe |

in aluminum through skin with up to 1.5 mm thickness |

|

SSP |

3K |

11D |

A |

(Sh) |

|

1 |

2 |

3 |

4 |

5 |

-

SSP – sub-surface probe for subsurface flaws detection.

-

Probe frequency:

“HZ” designates the Hz range; “К” designates the kHz range; “М” designates the MHz range.

-

Probe tip diameter, mm.

-

Probe type designation: “А”. А – Absolute.

-

Sh – Shielded sensing element. Absence of such designation mark means that the sensing element is made unshielded.